A robustified software design for a simple and accelerated industrialization

Centralized Electronic Architecture

A real paradigm shift for an ever richer user experience

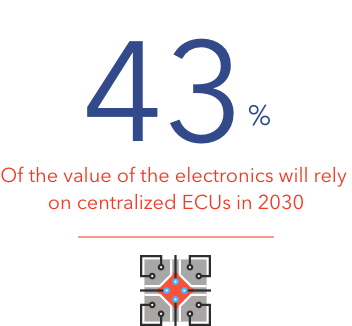

With the massive deployment of the connected vehicle and the perspective of the autonomous vehicle, the perceived value of electronic and software services will represent 40% of the value of the vehicle in 2030. Only a new way of developing electronic architectures in zones around centralized services and computing units, with a dissociation of the hardware and software life cycles, can meet these challenges. This underlying trend opens up new opportunities to bring ever smarter functionalities to users.

Car manufacturers are struggling to cope with this growth due to a significant inertia in their embedded electronics. They are based on solutions inherited from 35 years of incremental innovation, where each new feature addition results in the introduction of a new Electronic Control Unit in the car.

A car integrates up to 90 ECUs, each designed by a specific supplier that optimizes its economic equation by minimizing interactions with the rest of the system. This electronic infrastructure has the advantage of being robust and minimizing the industrial risk but struggles to value all the sensors and actuators integrated in the vehicles.

In addition, the design processes prohibit any major service update without taking over the electronics infrastructure, which leads to significant inertia on the part of manufacturers. The vehicle infrastructure is updated on average every 6 years.

In addition, the design processes prohibit any major service update without taking over the electronics infrastructure, which leads to significant inertia on the part of manufacturers. The vehicle infrastructure is updated on average every 6 years.

The switch to Zonal

architecture

Car manufacturers are engaged in the redesign of architectures, particularly towards zonal architectures.

The target is to be able to rely on centralized electronics to add new features by integrating software rather than by updating the vehicle infrastructure.

This is called Software Defined Vehicle. The challenge is to allow vehicle services to be updated throughout the vehicle’s life cycle at a high rate.

Representing barely 2% of architectures in 2020, the share of centralised solutions around zonal architectures will represent 43% of embedded electronics by 2030.

Our methodology

We transform into equations all the features of the car. The composition and integration of heterogeneous functions becomes child’s play. And here you are!

Our approach is simple: let the integrator compose his platform from all the hardware or software technologies available, regardless of the suppliers.

Extract information from your requirements management and modeling tools to build an equivalent model in Euphilia, enabling many automations including formal proof of safety properties and global coherence check of your specification.

It then becomes possible to automatically generate software safety mechanisms and monitoring code for use them on the embedded platform through our Receef software in order to exploit the full potential of our unique technology.

Easy deployment

Because the development process is a foundation of product quality, we are convinced that current processes must be enriched rather than replaced. Our products are an indispensable complement to existing tools that enable us to increase the results obtained tenfold. Thanks to the ability to develop import/export modules, we can interact with any kind of process with ease.

The reuse of all available models and specifications facilitates the deployment of additional features and the quick demonstration of safe integration.